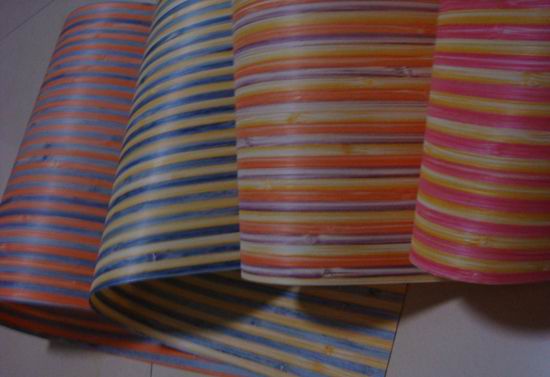

Dyed Bamboo Veneer

Bamboo veneer has 2 colors - natural and caramel in standard. The color choice is very small range and in order to expand more color choices range, bothbest introduced new manufacturing technology to produce various color of bamboo veneer ie dyed bamboo veneer. It is not stain on veneer surface, but color goes through veneer sheet thoroughly.

Manufacturing process: To make every veneer sheet has the color, we dyed bamboo strips with all-natural plant pigments to provide color throughout the entire bamboo, so the color is very inside of bamboo, not stained on surface. After bamboo strips are dyed, we will manufacture it to veneer. The manufacturing process includes boiling, drying, cutting, gluing, pressing and slicing. The boil will delete the color because bamboo already has been changed to colored bamboo strips. After pressing and slicing, every veneer sheet is colored and this technology gives very wide color range than before, same as wood veneer - many different choices, not just 2.

Application: Dyed bamboo veneer can be pressed on other carrier material like MDF, multiple layers plywood, chipboard etc, using for furniture, cabinets, sliding doors. Bamboo veneer backing is a cellulose fleece which is bonded with D3 water resistant PVAC glue. Dyed bamboo veneer has very clear and clean texture than bamboo veneer is stained in colors.

Styles: There are 2 styles for dyed bamboo veneer, one is one-color, the other mix-colors. One-color means the whole veneer sheet is just one color, for example, red, yellow etc. Mix-colors means the whole veneer sheet has multiple colors, one strip is green, one strip is red, one strip is grey etc. Mix-colors can be customized with special request.

Size: 2500 x 430 x 0.6mm

皖公网安备 34180202000049号

皖公网安备 34180202000049号