Bamboo Flooring Reviews

Bamboo flooring has 3 different structures because it has 3 different pressing methods. Bamboo flooring is pressed from layers of bamboo strips, either in horizontal direction or vertical direction or strand woven.

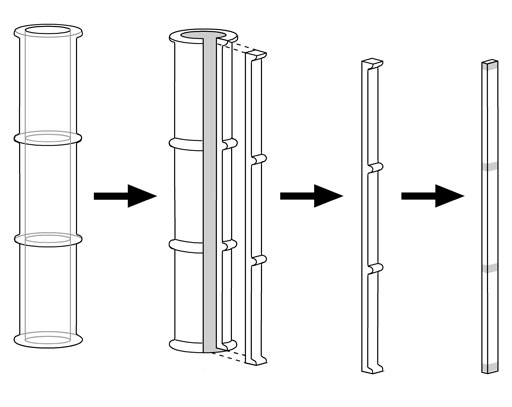

Bamboo stem is hollow. The hollow stems are cut to size and the outside knots and ridges are removed. The stems are then cut into strips, making it possible to easily remove the knot from the core of the stalk and the outside skin. Then thin bamboo strips are first treated with non-toxic pest repellent before being dried. After the strips of bamboo are completely dried, they are glued together to produce bamboo boards or sheets. Sending the glued boards into presser for 15 minutes, the rough bamboo plank is being produced.

From bamboo stem to bamboo strips

In the pressing, bamboo flooring is differed into 3 types - flat pressed, side pressed or compressed.

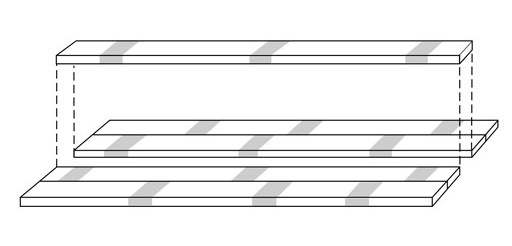

Horizontal is also called flat pressed. Flat press: Glued bamboo strips will be putting on the worktable piece by piece, referring the below photo, the hot presser will make the pressure both top and side. In 15 minutes, the planks will be pressed well and ready for milling and sanding. In flat pressed, bamboo nodes can be seen on the planks clearly and randomly. Horizontal bamboo is nice for small area installation to show the real bamboo. Horizontal bamboo can see its natural color variation from piece to piece and it is very random looking.

Flat pressed bamboo

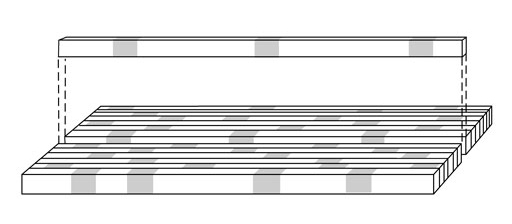

Vertical is also called side pressed. Side press: Glued bamboo strips will be standing together closely and it will be fastened by a thin plastic belt to let it be no movement. The stand planks will be sent into the presser, again hot pressure both top and side, after minutes, the planks will be out of presser to get cool down in the factory. Hot planks can't be milled and sanded immediately. Vertical bamboo flooring is suitable for the installation of public and large area because vertical bamboo has very less color variation, almost uniform look color.

Side pressed bamboo

Strand woven is also called compressed. Compress: Before gluing bamboo strips, all bamboo strips will be broken. Dry the strips and send strips into glue tank to get bamboo well-glued, with broken bamboo strips, the glue can go inside of bamboo strips quickly and easily. After gluing, the bamboo will be pressed by a heavy presser, the pressing is like MDF or HDF process. In the pressing, we weigh every bundle of bamboo strips to make sure each mold will have same weight, so the board can have same and high density. Strand woven bamboo is less color variation and looks like hardwood because of its dark color. Strand bamboo is suitable for installation of commercial area with high traffic.

The planks will be milled and shaped for Tongue and Groove or Click system, and then get milled planks sanded. The planks need be smoothly sanded, not heavy roughly. The well-sanded boards and sheets are coated with a protective UV coaling on all sides and exposed to UV rays. This is not only a drying process; it also hardens the boards or sheets, contributing to the strength of our flooring board. After coating, bamboo flooring is ready for package and delivery and installation in the house.

皖公网安备 34180202000049号

皖公网安备 34180202000049号